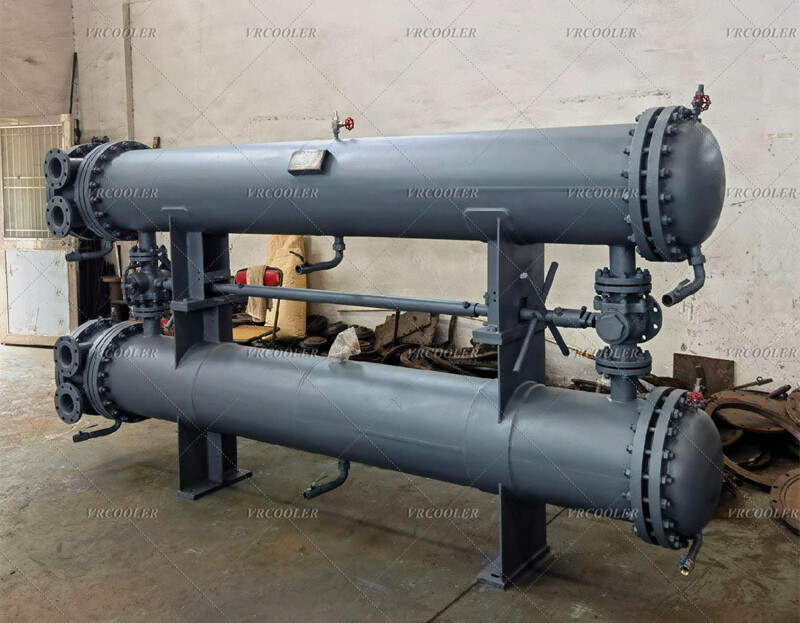

Evaporated Ammonia Wastewater Cooler

Ammonia evaporation wastewater cooler is a refrigeration equipment used for ammonia treatment in coking industry, its role is to reduce the temperature of evaporated ammonia wastewater to ensure the effect of biochemical treatment of wastewater.

Characteristics of wastewater media

High pollution load:

Ammonia nitrogen concentration: 1000-5000mg/L (can be reduced to 100-300mg/L after ammonia evaporation);

Phenolics: 200-1000mg/L (phenol, cresol, etc.);

Suspended solids (SS): 500-1500mg/L (containing coal dust, coke dust).

Corrosivity and scaling tendency:

pH: 8-10 before ammonia vaporization, 6-8 after ammonia vaporization, presence of carbonic acid corrosion caused by CO₂/HCO₃-;

Inorganic salts: high concentration of Ca²⁺, Mg²⁺ (hardness 200-500mg/L), prone to CaCO₃ scaling.

Core function of the cooler

Temperature control: cool the wastewater at the outlet of ammonia evaporation tower (90-105℃) to 40-50℃ to meet the requirements of subsequent biochemical treatment (microorganisms suitable temperature of 20-40℃);

Anti-blockage design: to cope with the high SS wastewater, to avoid clogging of the flow path leading to a decline in heat transfer efficiency (allowed SS concentration ≤ 800mg/L).

Core structure optimization

Heat exchanger tube selection:

Material: 316L stainless steel (Cl- corrosion resistance, chlorine ion tolerance ≤1000mg/L) or titanium alloy (strong acid corrosion resistance, suitable for high phenol wastewater);

Pipe diameter and wall thickness: φ25 × 2.5mm (large diameter to reduce clogging), the surface of the electrochemical polishing (roughness Ra ≤ 0.8μm, to reduce the tendency to scale). (Roughness Ra≤0.8μm to reduce fouling tendency).

Pipe plate and shell design:

Pipe plate connection: expanding and welding process (hydraulic expansion + automatic pulse welding), PTFE gaskets are set on the sealing surface (temperature resistance ≤ 260 ℃);

Shell form: U-shaped tube (eliminating the temperature difference stress, easy to clean mechanically), the shell program is equipped with a removable folding plate (the spacing of 0.6-1 times the diameter of the shell).

Anti-fouling flow path:

pipe flow rate: 1.2-2.0m/s (turbulent state, Re>10⁴, strong scouring ability);

shell course set spiral deflector (instead of traditional folding plate, reduce dead zone, pressure drop reduced by 30%).

Ammonia tower outlet wastewater (90-105 ℃) → shell flow (falling film flow)

Circulating cooling water (32 ℃) → pipe flow (2 pipe flow countercurrent)

↓

Cooling wastewater (40-50 ℃) → regulating tank → biochemical treatment system