Vrcooler's strong technological development capability, advanced computer software and management system, and highly qualified technical personnel enable the company to develop, design, and manufacture various process equipment and pressure vessels in time to meet the various needs of customers and provide perfect after-sales service.

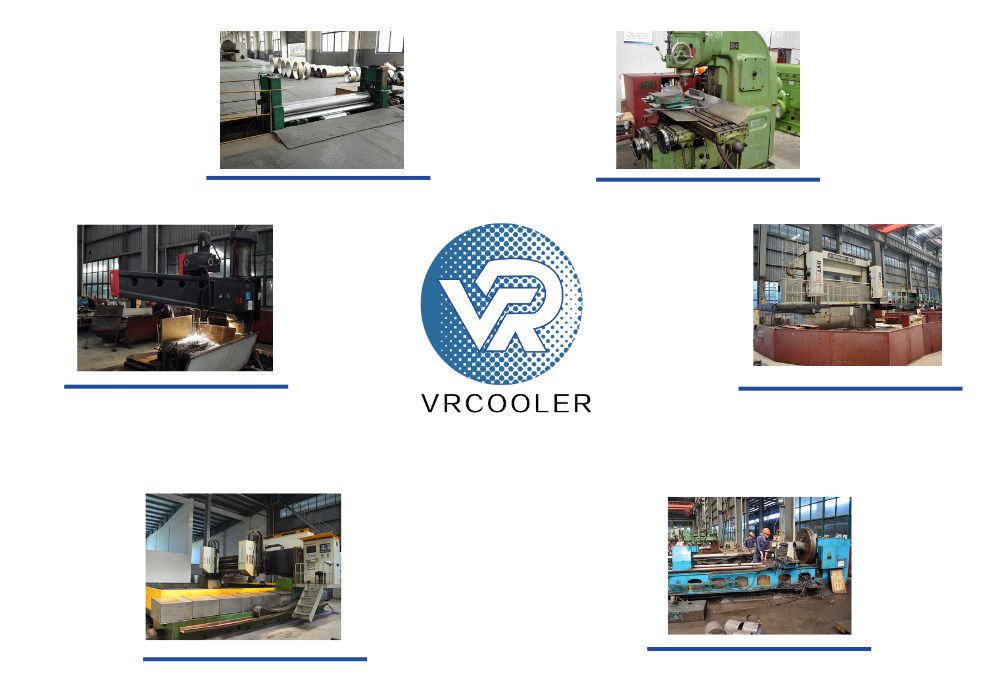

The company covers an area of about 40,000 square metres and employs 200 people, with CNC drilling and milling, vertical lathe, plate rolling machine, plate shearing machine, edge planing machine, edge cutting machine, large-scale bending machine, automatic pipe and tube plate welding machine, automatic pipe welding machine, melting electrode gas shielded welding machine, hydraulic pipe expanding machine, specimen heat-treatment furnace, sand blasting and other equipments.

In addition, in addition to the conventional special testing equipment tensile testing machine, chemical analyser, X-ray flaw detector, ultrasonic flaw detector, colouring detection, hardness tester, etc., the company also has the following proprietary equipment: infrared weld thermometer, eddy current flaw detection (ET), German-made metal direct-reading plasma emission spectrometer (PMI) and other welding inspection and testing equipment.