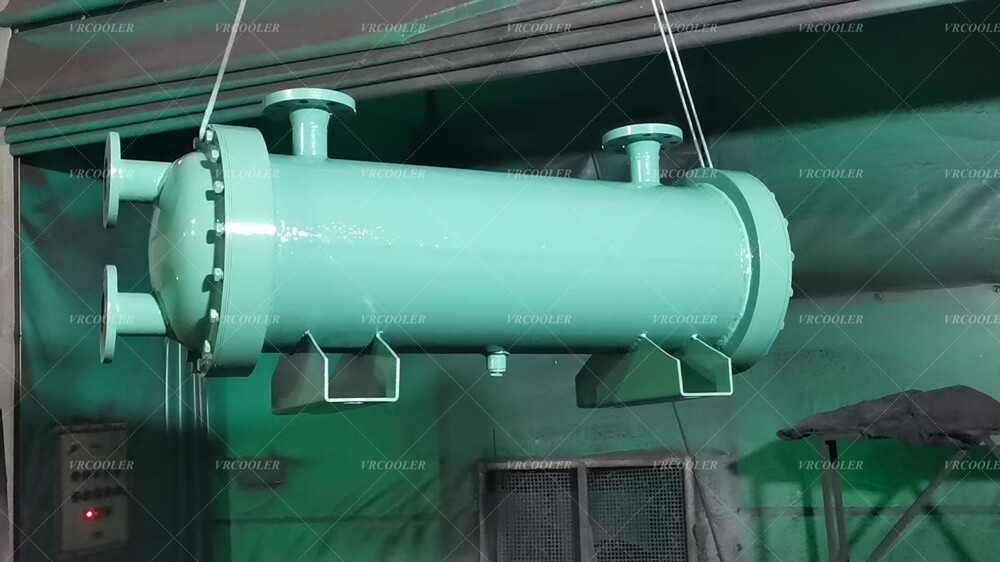

What Are Shell and Tube Heat Exchangers?

Shell and tube heat exchanger is a common type of heat exchange equipment widely used in industrial applications. Its basic construction consists of a shell and a number of tubes inside. The heat exchanger works by exchanging heat from one fluid (usually a heated or cooled fluid) in the tubes with another fluid (usually a cooled or heated fluid) in the shell. The fluid flows through the tubes and heat is transferred through the walls of the tubes to the fluid in the enclosure for temperature regulation. Depending on the need, the fluid that can flow inside the tube or inside the shell can be designed to flow either one-way or two-way.

What are the main applications of shell and tube heat exchangers?

Shell and tube heat exchangers are widely used in a variety of industries including petroleum, chemical, pharmaceutical, food processing, and power. They are commonly used for heat exchange in cooling and heating processes. For example, in petroleum refining, heat exchangers are used to cool hot oil or heat crude oil to improve fluidity. In the pharmaceutical industry, they are used to control reaction temperatures to ensure that chemical reactions are taking place at the right temperature to ensure product quality. In addition, heat exchangers are used in heat recovery systems to reuse waste heat to improve energy efficiency.