Why Choose Graphite Heat Exchangers?

When the medium is a strong acid such as sulfuric acid, hydrochloric acid, or nitric acid that ordinary metals cannot withstand, choose graphite;

When the industry demands high purity (e.g., pharmaceuticals, food) and requires avoidance of metal ion contamination, choose graphite;

When pursuing long-term stable operation and aiming to reduce total lifecycle costs (rather than focusing solely on initial costs), choose graphite.

The core rationale for selecting graphite heat exchangers lies in their irreplaceable performance under highly corrosive conditions—they perfectly resolve the industry's critical challenge of “requiring both efficient heat transfer and resistance to corrosion from strong acids and highly oxidizing media.” Simultaneously, they demonstrate significant advantages over conventional metal, special alloy, or other non-metallic heat exchangers in terms of long-term economic viability, safety, and adaptability to specialized applications.

Ultimate Corrosion Resistance: The “Nemesis” of Highly Corrosive Media

This is the primary reason for selecting graphite heat exchangers and their most fundamental competitive advantage. Graphite itself possesses exceptionally stable chemical properties. Except for strong oxidizing gases (such as chlorine and ozone at high temperatures) and a few specific molten salts, it can withstand corrosion from virtually all strong acids, strong alkalis, strong oxidizing media, and organic solvents. It is particularly effective against the most common “challenging” media in industrial applications:

Resistance to Strong Acids: Capable of long-term stable operation in 98% concentrated sulfuric acid, 37% concentrated hydrochloric acid, and fuming nitric acid. While common metals (carbon steel, 304/316L stainless steel) corrode rapidly in such media (e.g., stainless steel develops perforations within 1-2 weeks in concentrated hydrochloric acid), graphite can operate continuously for 8-12 years without leakage.

Resistance to Complex Corrosion Environments: In more severe scenarios like “acid + metal ions” (e.g., hydrochloric acid + Fe²⁺ in pickling waste) or “mixed acids” (e.g., sulfuric acid + hydrofluoric acid in metallurgical pickling), graphite avoids common metallic failures like “pitting corrosion” or “intergranular corrosion.” It also does not chemically react with the medium to form impurities.

No “passivation protection” required: Certain metals (e.g., titanium alloys, Hastelloy) require forming a “passivation film” in specific media to resist corrosion. Once this film is compromised (e.g., due to sudden changes in medium concentration or temperature fluctuations), corrosion accelerates dramatically. Graphite, however, does not rely on a passivation film, exhibits an extremely low corrosion rate (typically <0.01mm/year), and offers stability far surpassing that of metals.

Superior Thermal Conductivity: Balancing “Corrosion Resistance” and “High Efficiency”

The core requirement for industrial heat exchange is “high-efficiency heat transfer.” Graphite heat exchangers, while offering strong corrosion resistance, exhibit thermal efficiency far surpassing other non-metallic heat exchangers (e.g., glass, ceramics, plastics) and even outperforming certain metals:

High thermal conductivity: High-quality impermeable graphite achieves thermal conductivities of 110–150 W/(m·K)—over 100 times that of glass (approx. 1 W/(m·K)), over 500 times that of plastics (approx. 0.2 W/(m·K)), and nearly triple that of carbon steel (approx. 45 W/(m·K)). In practical applications, the base heat transfer coefficient for liquid-to-liquid heat exchange can reach 500–1200 W/(m²·K), enabling rapid transfer of substantial heat at small temperature differentials (e.g., rapidly cooling 150°C diluted sulfuric acid to below 50°C during dilution);

Excellent thermal stability: Graphite surfaces are smooth (machined roughness Ra ≤ 1.6 μm), resistant to fouling, and exhibit a low thermal expansion coefficient (only 1/5 that of carbon steel). Even under extreme temperature fluctuations (e.g., -20°C to 200°C), thermal expansion and contraction do not cause deformation of the heat transfer surface or poor contact. After long-term use, its heat transfer efficiency degradation rate is only 5%-10% (metal heat exchangers can experience degradation rates exceeding 30% due to scaling and corrosion).

Long-Term Cost Efficiency: “High Initial Cost” vs. “Low Total Lifecycle Cost”

Although graphite heat exchangers have higher initial procurement costs than conventional metals (2-3 times that of 316L stainless steel), their overall costs are lower over the “total lifecycle (8-12 years)” due to:

Extended Service Life, Reduced Replacement Frequency: Conventional metal heat exchangers require shutdown and replacement every 1-2 years under severe corrosion conditions (e.g., stainless steel lasts less than one year in concentrated hydrochloric acid), incurring equipment costs and downtime losses per replacement. Graphite heat exchangers operate reliably for 8-12 years, requiring only periodic maintenance, significantly reducing replacement costs and downtime risks.

Low maintenance costs: Graphite resists scaling and is easily cleaned (using mild agents like dilute acids or EDTA solutions), eliminating the need for complex maintenance like “acid pickling and passivation” or “weld repair” required by metal heat exchangers. Additionally, damaged graphite components can be replaced locally (e.g., a single graphite tube) without scrapping the entire unit, further reducing maintenance expenses.

Lower cost than specialty alloys: Specialty alloys with comparable corrosion resistance to graphite (e.g., Hastelloy C276, titanium alloy TA2) carry initial costs 3-5 times higher than graphite, highlighting graphite's significant cost advantage.

High safety and purity assurance: Tailored for specialized industry needs

In industries like pharmaceuticals, food processing, and electronics—where “medium purity” and “leak-free safety” are paramount—graphite heat exchangers' properties become critical selection criteria:

No Impurity Leaching, Ensuring Product Purity: Graphite's strong chemical inertness prevents reactions with media and avoids corrosion-induced leaching of metal ions (e.g., Fe³⁺, Cr⁶⁺) that contaminate products. For example:

In pharmaceutical antibiotic production, metal heat exchangers may cause drug degradation or efficacy loss due to metal ions; graphite heat exchangers meet GMP (Good Manufacturing Practice) requirements for “zero impurity leaching.”

In food processing for refined citric acid or lactic acid, graphite does not contaminate organic acids, ensuring food safety.

Low leakage risk: Graphite heat exchangers feature sealing structures (e.g., dual fluororubber O-rings, floating tube sheets) engineered to match material properties. Graphite inherently lacks the “stress corrosion cracking” risk common in metals, enabling long-term leakage rates below 0.01%. This prevents safety incidents from corrosive media leaks (e.g., sulfuric acid corrosion damage or personnel burns).

High structural adaptability: Suitable for diverse operating conditions

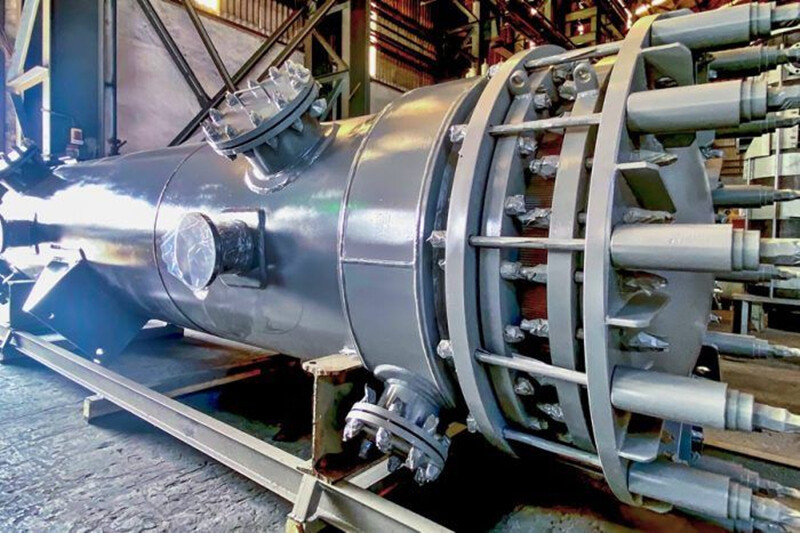

Graphite heat exchangers (especially shell-and-tube and block-hole types) can be structurally modified to meet varying process requirements, adapting to diverse operating conditions:

Temperature and pressure adaptation: Standard graphite heat exchangers are designed for temperatures ranging from -20°C to 200°C. Specially modified graphite (e.g., metal-impregnated graphite) can withstand temperatures exceeding 300°C. Design pressure can reach 0.6 MPa (shell side), meeting pressure requirements for most chemical and metallurgical processes (e.g., sulfuric acid dilution or acid pickling heating typically requires pressures <0.4 MPa).

Flexible Heat Transfer Area: Customizable heat transfer area (ranging from several square meters to hundreds of square meters) based on production capacity requirements. Examples include 5-10m² graphite heat exchangers for small pharmaceutical workshops and 100-300m² units for large sulfuric acid plants.

Adaptable to Multiple Heat Transfer Modes: Beyond common “liquid-liquid heat exchange” (e.g., sulfuric acid dilution cooling), it supports “gas-liquid heat exchange” (e.g., gas cooling during hydrochloric acid stripping) and “condensation heat exchange” (e.g., NO₂ condensation in nitric acid production). This is achieved by adjusting tube bundle arrangements (equilateral triangle/square) and shell-side configuration (single-pass/multi-pass) to optimize heat transfer efficiency under varying operating conditions.