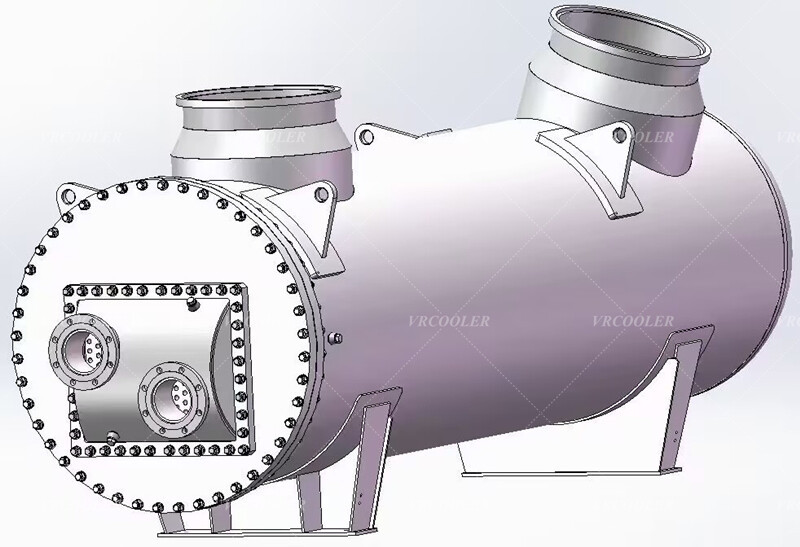

Shell and Tube Heat Exchangers Biological Media and Water Heating

Principle of operation

Heat exchange process: the biological medium (e.g. biosludge or other biological material) flows through the shell of the heat exchanger, while the water flows in the internal piping. Heat is transferred from the biological medium to the water, thus heating the water.

Design considerations

Material selection: Corrosion and temperature resistant materials need to be selected to suit the characteristics of the biological medium.

Direction of flow: either a downstream or counter-flow design can be used, with counter-flow designs usually providing higher heat transfer efficiencies.

Heat exchange area: Calculate the required heat exchange area according to the flow rate and temperature difference of the fluid to ensure effective heat exchange.

Application Scenarios

Wastewater Treatment: In wastewater treatment plants, biological media are heated to facilitate the biodegradation process.

Bioenergy utilization: In bioenergy generation or biofuel production, the biological medium is heated to extract energy.

Maintenance and monitoring

Periodic inspection: Keep the heat exchanger clean and regularly check for scaling or corrosion.

Temperature and flow monitoring: Real-time monitoring of temperature and flow to ensure efficient operation of the system.

Through good design and maintenance, the shell and tube heat exchanger can effectively heat water to support the treatment and utilization of biological media.