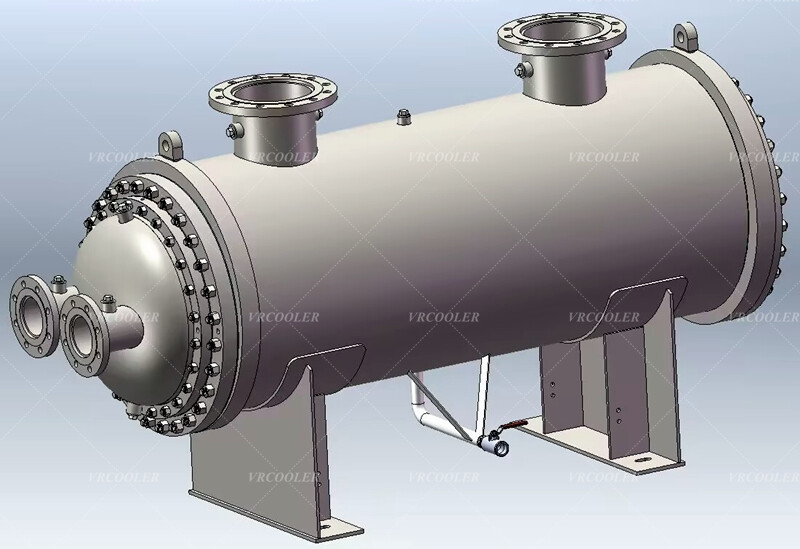

Shell and Tube Heat Exchangers: Cooling Seawater with Glycol

Principle of operation:

Shell and tube heat exchanger consists of a shell and an internal tube bundle in which seawater flows inside the shell and glycol flows inside the tube bundle.

Heat is transferred from the seawater to the glycol through the walls of the tubes to achieve the cooling effect.

Selecting Materials:

Because seawater is corrosive, shell and tube heat exchanger materials generally need to be corrosion resistant, such as stainless steel or titanium alloys.

Design considerations:

Calculation of flow rate and heat transfer area to ensure effective heat exchange.

Glycol flow and temperature control to ensure that it does not overheat during the cooling process.

Application Scenario:

is commonly used in offshore engineering, chemical plants, and power plants where cooling systems are required.